This article is written for people who choose DTG printing for their hoodie business. Nowadays, DTG printing is a popular choice due to the following reasons. It allows us to custom on demand. Compared to other printing methods, it is more sustainable and eco-friendly. What’s more, buying DTG printer is affordable for many people.

So, what is DTG Printing?

DTG refers to Direct To Garment. Generally, it means to use the machine to directly spray the ink directly on the fabric. The fabric often has a big proportion of cotton. The operation is just like how we print some patterns on paper.

In fact, it is the paper printing that inspired people to study and create DTG printing. It was invented in the 1950s. Now it becomes very popular in the fashion industry.

The Best Fabric For DTG Printing

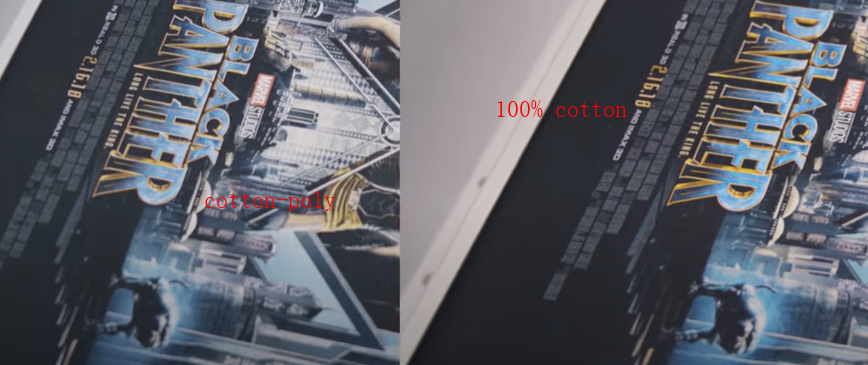

The best fabric is 100% cotton. The more cotton the fabric contains, the better the print effect is. It is because the cotton can absorbs the ink best and lasts longer. If the material contains less cotton, we will see that the printing is somewhat blurry because other fabrics like polyester are repellent to this ink.

If the fabric does not absorb all the ink, the printed pattern is likely to have distortion. And after plenty of experiments, we have found that it would be better to use DTG printing if the fabric contains at least over 50% cotton. The following pictures are comparison results between two types of fabric, you can find the difference.

The Operation of A DTG Printer

The operation includes three steps: pretreat, print and curing. Pretreat should be done before printing because it allows the white ink to look nice and vibrant. Print is much easier, we can follow the instruction and press the start button. Before printing, you should also make sure that your design is high quality with high resolution. Then it comes the curing process. For light fabric, it takes about 35 seconds. For dark fabric, it takes about 90 seconds.

Is DTG Printed Pattern Durable?

At present, many custom fashion brands will choose this printing while worrying about its durability. Well, its durability is actually similar to the traditional printing methods. The durability are closely related to the ink quality, perfect treatment and curing time. It could last very long if those conditions are met.