Water-Based Printing

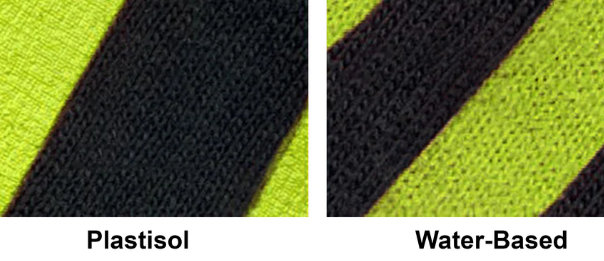

Water based printing is suitable for simple logo designs. It is commonly used on lighter-colored fabrics and has no specific requirements for fabric ingredients. The advantages of water printing include being breathable, touching almost the same as the original fabric, and the color will be a little darker.

Plastisol Printing

Plastisol printing is also suitable for simple logo designs. And the print effect would be better if the designs are on darker fabrics especially black fabric. Compared with water-based printing, it has an obvious sense of plastic, and the whole piece of printed pattern may not be breathable.What’s more, water printing works better on lighter-colored fabrics while plastisol printing works well on any fabric.

Puff Printing

It is a kind of special printing method. After the resin coating of foaming is applied to the textile, the pattern will be foamed and embossed after high-temperature steam. Puff printing has a good three-dimensional effect and is also a popular printing method for t-shirts and hoodies in recent years.

Sublimation

Sublimation is commonly used in full printing clothing styles such as polyester full printing sweatshirts, t-shirts, beach pants, skirts, jumpsuits, pajamas, etc.

It’s usually suitable for polyester and can achieve a good effect, a soft surface with lower prices.

Note: Since sublimation is applied on white fabric, one side of the fabric is fully printed, and the back side is still white.

DTG(direct-to-garment)

DTG printing is used for cotton fabrics. If you want to print complex colors with a gradient effect, it’s better to choose DTG printing. The price is relatively high, and the size is generally limited to 40cm.