When it comes to custom printing and merchandising, sublimation and screen printing are the two most popular methods for custom printing and merchandising. Thus, many business owners find it difficult to decide between these two methods. So, sublimation vs screen printing: which one is superior? Let’s find out!

Screen printing and sublimation are different techniques to produce long-lasting, high-quality prints. Screen printing takes a long time and requires a stencil, thick inks, and a heat source. Sublimation printing is quick and easy because it uses a chemical process for bonding.

It is important to examine the characteristics of both of these methods before choosing one. There are many advantages and disadvantages to both of these methods, which can have a big impact on your business procedures and the final outcome. So, before deciding on one of these methods, it’s important to learn more about them in order to make an informed decision.

Understanding Sublimation And Screen Printing

Sublimation and screen printing are two of the most widely used methods of creating custom prints on accessories, apparel, clothing, and so on. Both of these methods are effective for creating high-quality and durable images on different products.

Sublimation is a process that uses heat and pressure to connect chemically or bond dye to the fiber strands within synthetic fabrics. It is capable of producing robust and distinct designs. As a result, this new printing method is quickly gaining popularity among experienced printers and entrepreneurs.

This method also uses the full computerized color scale of the CYMK printer model. That means you can print full-color photographs or images with the sublimation technique. So, if you want to print your garments from seam to seam, the sublimation printing will be your best option. It is better suited to on-demand production.

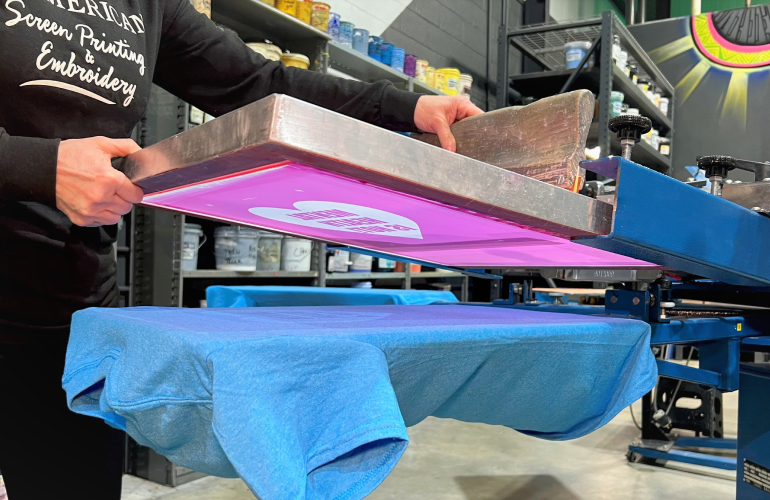

At the same time, screen printing is also an effective printing process. Screen printing obtains the desired image by using a woven mesh screen that supports an ink-blocking stencil. The screen stencil creates open mesh areas that transfer ink or other printable materials by pressing through the mesh to create a sharp-edged image onto a substrate.

Many people popularly refer to screen printing as “silk screen printing”. Here, only one color is printed at a time, therefore, several screens can create a multicolored image or design. It is most appropriate for printing a small design on a garment, product, or accessory. For bulk manufacturing, traditional screen printing is more suitable.

So, these are the primary understanding of sublimation screen printing. Although both sound relatively simple to print your favorite designs, there is a larger picture to see. Sublimation printing vs screen printing can be a turning point for your manufacturing or printing business in terms of quality, production, and results.

What Are The Difference Between Screen Print And Sublimation?

Learning about the difference between screen print and sublimation can help business owners select their preferred printing method. At the same time, clothing brands, retailers, and business operators can get many competitive advantages in this way. So, here are some of the significant differences between sublimation and screen printing.

Quality Of Printing

Sublimation printing quality is outstanding for its vibrant color properties. This printing will give you distinct, bright color tones that will not fade over time. Multi-shaded images are easily printable without damaging their quality. Moreover, the color is embedded in the fibers of the fabric through sublimation. Hence, it does not wash out easily, nor does it crack or peel.

In comparison, the quality of screen printing may be poorer. Screen printing is excellent for creating designs with a strong and tactile contrast of colors and textures. The plans appear sophisticated and tasteful through this process. However, because the ink sits on top of the garment, the ink may crack and peel after repeated washings, and the colors may fade.

Durability Of Printing

Sublimation prints outlast screen-printed designs. Because the dye bonds are penetrated deep beneath the fabric’s surface, sublimation designs will never break, peel, or fade. As a result, sublimation printing is both durable and long-lasting. At the same time, the color quality, intricate design, and shapes remain consistent throughout many washes and use.

Screen prints stay strong and maintain their quality through many washes. But eventually, the raised-ink configuration will break or peel away from the fabric. However, screen prints use a particular type of ink known as plastisol ink. This creates a highly-durable printing quality for your products. As a result, while screen printing is durable on its own, it pales in comparison to sublimation.

Printing Materials

Sublimation printing works best on light-colored polyester, polymer-coated fabrics, or polyester blends. This printing process is best for many other materials and fabrics, including lycra, spandex, neoprene, nylon, and so on. You can sublimate on cotton fabrics, but the heat transfer will not be up to par because heat transfer printing is better suited to synthetic materials.

The most popular choices for textile screen printing are various types of cotton fabrics and cotton blends. The reason is that ink adheres to cotton and cotton blends, and screen printing is better suited for such fabric fibers. Silk screening is also commonly used in paper printing. Screen printing on metal, wood, plastic, and other materials is possible with specialty inks.

Complexity Of Designs

Sublimation printing can effectively print various complex and intricate designs on your chosen material. This becomes possible because the sublimation technique involves printing a digital image directly onto transfer paper. In this process, you basically put everything in before printing by creating a high-quality digital image with various graphic design software.

Supporting complex designs is more challenging with screen printing. In this process, you must first create your stencil for a screen print. You can create detailed stencils, but this usually involves creating a convoluted light emulsion that functions similarly to a photo negative. So, you’ll need a lot of chemicals, a lot of expertise, and a lot of patience to create complex designs this way.

Colour Range

The color range for sublimation printing is very diverse. This process can work with the entire computerized color scale of the CYMK printer model. As a result, for multicolored prints, the sublimation process works much better. Sublimation printers easily mix primary colors to produce colorful, complex images. These designs look best on light-colored fabrics.

In the screen-printing process, the color range is comparatively limited. Because the colors must be separated and applied one layer at a time. In most cases, screen printing requires hand mixing of the desired color shades. Each color must be printed separately, which increases the time needed to print the garment. So, this limits the possibility of applying many colors.

Environmental Sustainability

Sublimation is a good option for an environmentally friendly and sustainable method. Demand-driven sublimated products eliminate overproduction. In addition, sublimation ink is non-toxic and eco-friendly, and sublimation uses less water than other dye transfer techniques. Furthermore, waste is kept to a minimum during the manufacturing process.

Alternatively, screen printing has a few cons regarding the sustainability factor. Manufacturers almost always need to order in bulk if they choose the screen-printing method. It creates the risk of leftover stock and product waste.

Furthermore, the most commonly used plastisol inks in screen printing are toxic and non-biodegradable. Water-based inks that are more environmentally friendly are frequently used in screen printing. As a result, it is not the most environmentally friendly method of printing.

Cost Efficiency

Sublimation printing follows a repetitive process of manufacturing. That means, every time you make a shirt with sublimation printing, you have to put in a similar amount of effort. Although it may not be a big hurdle, it allows you to make one product as well as ten, keeping the price the same. So, sublimation is more cost-effective when producing custom-ordered t-shirts.

Screen printing, on the other hand, is much more cost-effective when it comes to bulk manufacturing. In case the manufacturer needs to make a large-scale order of a single design, screen printing will be the best option because you can use the same tools, time, and effort repeatedly to make several screen-printed products. Thus, you can attain cost efficiency.

Suitable Manufacturing Process

Subliminal printing is more suitable for repetitive and on-demand order fulfillment manufacturing processes. Because this process allows you to create customized products according to customers’ orders, this printing process has an average output rate of 60 pieces per hour. As a result, sublimation printing is the most popular method of garment printing.

At the same time, screen printing is better suited for the batch manufacturing process. This printing process is hard to set up and costly for one-time orders. But for bulk manufacturing, there is a cost-effective factor associated with it. For orders of the same kind, without many variations, the screen-printing process will be the better choice for business owners.

Which Is Better, Sublimation Or Screen Printing?

The better printing process will depend on the business and production requirements of the organization. Both of them come with different characteristics for getting effective results. So, a business must decide which one suits them better.

As we have learned from the differences between sublimation printing and screen-printing processes, both of them have many distinct characteristics. At the same time, these printing methods are best suited to specific manufacturing processes. When you connect the manufacturing process and the printing process, then the organization will get many advantages. However, choosing the incorrect printing mode will also result in disadvantages. Sublimation has numerous advantages. It can create intricate designs with vivid colors. You can print everything in one piece and avoid paying extra for different designs or colors.

Because the ink becomes a part of the fabric, the clothing is less likely to peel, fade, or chip. As a result, the garment is more durable, cleaner, and lighter.

However, a disadvantage of sublimation printing is that it only works well on polyester or polymer-coated surfaces. For cotton fabrics, there may be better choices than cotton fabrics. At the same time, subliminal printing could be more efficient for bulk manufacturing. If you choose a subliminal printing process for a large volume of output, it may cost you considerably.

Alternatively, screen printing is a remarkable way to create products in large quantities. It is perfect for batch production. So, if you want to print a similar design on a large scale, this process will save you money. The printing work is also very sophisticated and gets effective results. It will give you exciting textures and raised designs on cotton fabrics.

Nevertheless, screen printing has a few disadvantages. It is less durable than the subliminal printing process. Here, the ink does not chemically bond with the fabric. It sits on top of the material after the printing is finished and dries afterwards. So, after several washes, the quality may become defective. The design and printing may crack or peel eventually.

Which Printing Method Should You Choose For Your Business?

For on-demand production, the best orientation method is the subliminal process. But in the case of large orders and similar designs, the screen-printing method will be the best option for you.

When it comes to drop-shipping products, subliminal printing is the best option for your business. That means if your company sells products that need an on-demand manufacturing process, subliminal printing will give you the best results. It can get durable, vibrant, and customized products created from a variety of materials.

At the same time, the screen-printing process is the perfect solution for batch production. So, if your business deals with creating bulk orders, for example, printing similar t-shirts or clothing, then the screen-printing process is the best solution. It can be cost-effective and speedy for large orders. Thus, business owners can safely choose this option for large orders.

Conclusion

To sum it all up― sublimation vs screen printing, both of these methods are effective for getting the targeted results in printing. By learning their characteristics well, business operators and retailers can support their businesses better.

In this way, various companies can gain a competitive advantage in the market by choosing the best printing process for them.