Quality means satisfying the customer’s needs. Incorrect quality standards could therefore result in failures. Consider importing the best custom t-shirts for your fashion business to offer the finest quality clothes to your customers. But you realize that you are receiving numerous product returns because you haven’t defined the inspection criteria.

On the other hand, a customer visits your shop to check the best hoodie designs but finds your design faulty resulting in losing customers. Quality control and inspection have become an integral part of your success puzzle. However, maintaining the appropriate quality standards requires effort. From initial testing to discovering the needs of potential customers of the products through development, design, specification, and controlled manufacturing to sale.

Numerous factors determine the quality, visual, and durability of manufacturing. We look at problems boutique clothing wholesale businesses might face and try tricks to solve those problems for managing bulk quality control.

Issues That Boutique Clothing Wholesaler Encounter In Quality Control

Fashion brands face a variety of issues from production to shipping. Boutique clothing wholesalers encounter several problems in quality control like stitching, size issues, color, fabric, or material defects, faulty zippers, indecent trimmings, missing buttons, broken color patterns, stains, uneven stitches, mismatching of threads or buttons, etc. If you want to stay on top of the competition, your apparel needs to speak to your targeted audience. You should learn how to fix these problems by implementing the following tested tricks and managing your quality control checks.

Five Tested Tricks To Manage Apparel Bulk Quality Control

Before making the final shipment, quality checks have required to confirm the quality of clothing products. If you are shipping the best custom t-shirts for an established clothing brand or a variety of apparel for boutique clothing wholesale, you must set specific quality requirements. In this way, you can inspect the final product before shipment. For quality control in mass production, we recommend the following tested tricks.

1. Inspecting And Testing The Clothing Material

The most critical aspect of production is the raw material, which is a unique substance. If the fabric is of poor quality, no matter how attractive the clothing designs are or how perfectly stitched the garment is, the entire product will be flawed. Inspecting the textile material should be the top priority once fabrics reach the warehouse. Similarly, if you want to create the best hoodie designs, for example, you must perform design quality assurance. Density and softness are the characteristics of the textile material that determine its quality, not its weight or thickness.

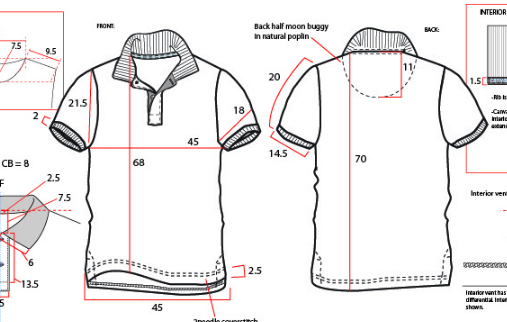

You should develop a checklist for quality control in garment inspection. Many manufacturers create a checklist for garment inspection before production begins that outlines quality control requirements, and product specifications. The checklist is a detailed document that serves as a guideline for the clothing manufacturer during the entire production process. Include the following points in your garment inspection checklist.

Clothing Requirements

Clothing requirements include a combination of things for inspection such as apparel material, weight, size, dimensions, color, markings, and labeling. It consists of all the requirements issued by the shipper. Manufacturers like MGOO Fashion check the apparel quality to make sure they meet the standards set by the clients. Our goal is to satisfy boutique clothing wholesale customers with the finest clothing and best hoodie designs, or other clothing style designs based on accurate specifications and high-quality standards.

Garments Packing and Labeling Requirements

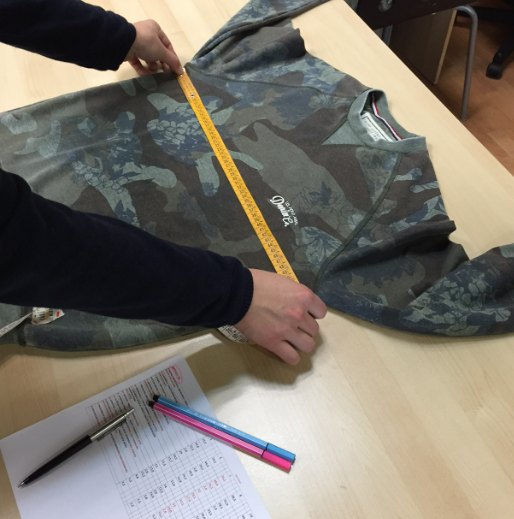

Garments checking requirements determine whether a product or part of a product has passed or failed. The packing and labeling checklist comprises all the prerequisites from shippers like packaging weight, dimensions, boxing material, packaging procedure, marking requirements, and labeling specifications. In addition, a list of tools and instruments has required for taking measurements is also mentioned in the garment inspection checklist.

Testing The Quality Of Best Custom T-Shirts

If you are concerned about your stakeholders and want them to dress up elegantly and not poorly, you must check the quality of your custom t-shirts. Providing the best custom t-shirts will leave a lasting impression on your stakeholders. Before shipping the customized apparel to your customers, inspect the durability, check the quality of the colors, images, and prints, and consider the washing or caring requirements.

Interested in getting the best custom t-shirts for your boutique clothing wholesale? MGOO Fashion facilitates the order of any size by incorporating different techniques of customization and printing. We have helped 4000+ clothing brands to boost their businesses. Whether you need to regulate a mass production or need a small order of a few pieces, we will provide whatever is required as we have got your back.

2.Cutting And Sewing Quality Control

Fabric spreading and after-cut inspection are the two stages of the process. When arranging piles of fabrics, quality control is crucial. In the fabric spreading stage, you can inspect pattern marking, fabric tension, and any defects in or matching of fabrics. In contrast, after-cutting inspection includes checking the miscuts or notches.

Sewing quality inspection includes a range of parameters such as clean stitching, accessories checking, embroidery, or printing inspection, seam per inch, fault stitching, and trimmings checking.

3.On-Site Apparel Testing Before Shipment

On-site checks are not just for electronics or functional products, so do not disregard on-site inspection when inspecting clothing. You can ensure the durability and functionality of the best custom t-shirts during on-site apparel testing before shipment.

You can conduct fitting tests, crocking tests, stretch tests, garment color checks, or stitch strength checking. Further, if you are developing creative hoodie designs for a brand, make sure to implement design quality assurance before finalizing them.

● Fitting, Crocking, And Color Inspection

The inspection team will check the size of each clothing piece by putting it on a mannequin. To avoid any future hassles, you should make sure that dummies are available before shipments to ensure apparel fitting. A crocking test involves repeatedly rubbing white fabric over colored fabric to see if the color transfers.

●Garment Stretch Testing

To check the elasticity of the fabric, the inspection team will stretch the fabric or elastic straps. During this test, the fabric or elastic strap must show adequate elasticity without breaking the stitches.

● Stitch Strength Checking

Stitch strength checking involves pulling the edges or seams of apparel with normal force. After the test, the inspection team will reveal any cracks in the stitching.

●Design Quality Assurance To Deliver The Best Hoodie Designs

The inspection team uses quality assurance techniques in the designing, production, and evaluation process to ensure the quality standards satisfaction of a clothing brand. In every phase of the production procedure, MGOO Fashion follows design quality assurance methods to prevent errors that might be overlooked. Our quality control process includes checking visual designs, cross-checking developed designs, inspecting the digitalization of artwork, image sharpness, and color vibrance to ensure that you receive the best hoodie designs.

4.Conducting Laboratory Tests For Clothing Inspection

Occasionally, an intense quality check is needed for your clothing before meeting the quality expectations. Apparel laboratory testing is conducted on a sample of the entire production by sending it to a lab for checking. You can test colors, pigments, dyes, spangle, and the fabric base in laboratories.

5.Implementing A Total Quality Management Approach

A Total Quality Management (TQM) Approach is a product management technique that ensures product success by satisfying customer needs. In TQM, all organizational departments and divisions are involved in the production process. The goal of TQM is to eliminate product waste while seeking continuous improvement. You must implement total quality management in your boutique clothing wholesale business to offer customers high-quality products at a low price.

At MGOO Fashion, we provide a one-stop solution for manufacturing high-quality clothing and delivering quality control reports daily to meet customers’ needs. From classic designs to amazing graphics, we have the selection you need for the best custom t-shirts, sweatshirts, pants and shorts, polo shirts, best hoodie designs, etc.

Finally, Here Are My Thoughts

High-quality products leave a lasting impression on your targeted audience. Quality checks prevent defective products from harming your business credibility. Therefore, make sure your clothing products meet regulatory standards and deliver the highest value.

Interested in attracting new customers every season and keeping the old ones coming back? MGOO Fashion pushes you one step closer to customer acquisition. Management of apparel bulk quality control is an uphill battle. While doing so, we pay attention to specific details as we are concerned about your finished garments. We put efforts into creating the best custom t-shirts and developing the best hoodie designs, other custom clothing designs for your clothing brand by using the appropriate approaches and planning.

If you want to know how to find professional clothing manufacturers for your clothing line, welcome to click to read this article.