T-shirts are common and popular clothing items. But do you know how they are made and how different designs are printed on them? T-shirt printing is a unique and creative process that requires various techniques and materials.

In this article, we will talk about the advantages of t-shirt printing in the fashion industry and the 8 types of shirt printing. We will teach you the basics of t-shirt printing and how to pick the best way for your goals.

Advantages of T-Shirt Printing In The Fashion Industry

T-shirts are like empty spaces that you can fill with any design or message you want. You can style and design a simple t-shirt in many different ways. If you’re going to start a t-shirt business, you can benefit from custom printing designs. Let’s take a look at those benefits.

Personalized design

One of the best things about t-shirt printing is that you can customize the design to your preference. There are no rules or limits for making a t-shirt design. That’s why t-shirt printing is popular in the fashion industry.

You can create unique and stylish t-shirts with text, graphics, photos, and more if you have a clothing business. You can also design and print t-shirts with your company slogan, name, or logo to advertise your business.

Different printing methods

You can choose from various methods to custom print t-shirts. For example, you can use screen printing if you have a large business and need to print many t-shirts.

But if you have a small business or need to print fewer t-shirts, you can use DTG printing. You can choose the method that suits your budget and quality needs.

Affordable

T-shirt printing is fast and cheap compared to other printing technologies. That’s why many businesses use t-shirt printing to promote their brands.

It is more effective and less costly than other marketing media like TV ads, flyers, posters, and banners. It is also easier and faster to print on a simple t-shirt.

High-quality design

Whatever design you choose to print on a t-shirt, it will become an image on the fabric. The ability to print high-quality graphics quickly was one of the main reasons why many businesses chose t-shirt printing in the past.

A simple t-shirt can change completely with the sharp images that are produced and printed. This is why every business owner should focus on making t-shirt designs of the highest quality and printing them with the best method.

Flexible and versatile

Another thing that will make you love t-shirt printing is its flexibility and versatility. As I said before, a T-shirt is like a blank space. So, hire a professional designer to make the t-shirt. You can create a unique, creative, attractive design that stands out.

This allows the owner and the designer to show their creativity and use their ideas, catchy slogans, or color schemes. There are no boundaries for making a custom t-shirt.

Promotional materials

T-shirts are still one of the most powerful and successful marketing tools today. Anyone of any age, gender, or class can wear them.

Everyone loves T-shirts—boys and girls, men and women. T-shirts are also suitable for both formal and informal occasions. T-shirts are perfect for brand marketing.

Inspires customer loyalty

Giving away free custom-branded t-shirts can increase brand loyalty. Businesses now offer printed t-shirts as gifts instead of only using websites or events. It helps to keep existing customers and make new ones feel special.

10 Best Methods for Printing Shirts

You already know the benefits of shirt printing in the fashion industry. Now, let’s talk about the 8 best methods for shirt printing:

Heat Press Printing

This method requires thermotape, vinyl cutters, and cover sheets. It’s a great choice for beginners or home artists, even though it may not deliver the highest quality. The design is created on a computer using an inkjet or laser printer.

The only suitable material for printing is iron-on transfer paper. After printing, the design is heat-pressed or ironed onto the shirt.

This method is ideal for home designers due to its low initial cost and simple setup. You can use images from the internet or your phone, but if you want to create original artwork, you’ll need to learn how to use graphic design tools.

However, heat press printing may not be as durable as HTV or screen printing, and it doesn’t work well on dark-colored shirts or heat-sensitive fabrics.

Pros

●Can accommodate special needs

●Sharp and quality photos

●Durable against fading and abrasion

●Low cost for small print runs

Cons

●Not effective for large orders

●Less effective on dark clothes

●Not suitable for heat-sensitive fabrics

DTG Printing

You’ll need a DTG printer and a heat press for this method. If you can afford a DTG printer, it’s one of the best options for producing many high-quality T-shirts. The printer allows you to print ink directly onto the fabric.

You can use design software like Photoshop to create the perfect image for your T-shirt. After uploading the image from your computer, you can use the DTG printer to print the design onto your shirt.

DTG printing is the best choice for incorporating complex designs. However, you need a high-quality printer to get the desired results. Also, DTG shirts should be hand-washed in cold water and air-dried to prevent the image from fading quickly.

Pros

●Can create unique effects

●Durable design that can last over 60 washes

●High detail and flexible pattern

●Uses eco-friendly water-based ink

Cons

●High cost due to expensive textile printers

●Only works well with cotton materials

●Colors may fade over time

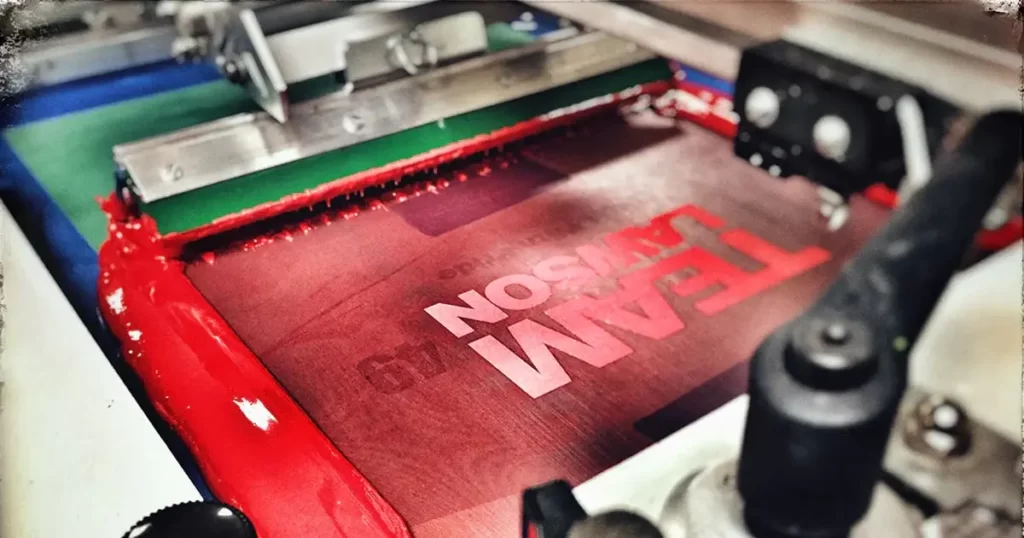

Screen Printing

This method requires presses, screens, exposure units, and dryers. It’s one of the most commonly used methods for creating T-shirts. You’ll need a nylon mesh and a stencil. The mesh holds the stencil in place, which you can use as a guide for your T-shirt designs. The blank areas in the stencil are where the ink will be transferred to the fabric.

Screen printing is known for delivering reliable and high-quality results. It’s suitable for mass production. While many believe that screen printing can only produce graphics with a limited number of colors, it can actually produce vibrant and detailed graphics with the right technical skills.

Pros

●Fast and versatile

●Rich, vivid colors

●Profitable for large orders

Cons

●Long process of preparing and customizing the design

●Not effective for detailed drawings and realistic photos

●Difficult to use with multi-colored designs

●Not profitable for short runs

Belt Printing

You need a belt printer for this method. Belt printing is a type of screen printing that uses a large belt to move the shirts to the printing stations. The belt stops the shirts and lowers the print heads to print the designs. This is different from a circular machine that moves the shirts on small tables to the print heads.

Belt printing lets you be creative and make unique designs that cover the whole shirt. You can print over the seams, the collar, the sleeves, the hem, or all of them. The designs look like a complete coating on the shirt. Belt printing uses water-based ink to make the designs smooth. You can add more colors even if you use only one color.

The method gives your shirts a retail look. The large screen makes each shirt look different. You may see some folds and wrinkles in the designs, but that is not a flaw.

Pros

●More luminous

●Less expensive

●Easily pliable terrain

Cons

●Lack of design consistency and speed

●Difficulty in printing registration in various colors

Dye Sublimation Printing

This method requires a heat press, release paper, inks, and a sublimation printer. Dye sublimation printing uses a special dye that dries quickly on the fabric. You need to apply heat and pressure to transfer the design to the shirt. The dye turns into gas when it is heated, and the fabric expands. The gas goes into the gaps in the fabric.

When the heat is removed, the fabric shrinks and traps the gas in the shirt. Dye sublimation printing does not work well with cotton fabrics because it transfers heat directly to the fabric. It works best with polyester fabrics.

Pros

●An infinite number of colors

●Durable patterns

●Ideal for continuous fixes

Cons

●Spot coloring

●Only works well with polyester

Discharge Printing

In discharge printing, a special material like hydrosulfite or chlorine is printed onto a darker base color. This material bleaches the color, leaving behind a light or white design. Unlike other methods that add color, discharge printing removes it. The result is a soft print that reveals the texture of the shirt.

This method can also serve as a base for additional colors. However, the exact color effects may vary due to the color-changing nature of the material. Despite this, it’s an effective way to introduce color to dark fabrics.

Discharge printing is safe and eco-friendly. The ink doesn’t irritate the skin, and the process uses water. It’s similar to regular screen printing but with a twist. You preserve part of the shirt design with a stencil, then bleach out the remaining color. Emulsions are needed to protect the stencil during printing.

You can even try this method at home to create cool, vintage-looking shirts. Instead of using a white background for printing, a dye that blocks color is used. Then, a color-bleaching material is used to create a design on the colored base. The method uses a water-based material that is gentle on the fabric, making it suitable for delicate fabrics.

Pros

●Unique look

●Retro style shirts

Cons

●Expensive for both people and businesses

●Time-consuming

Heat Transfer Vinyl Printing

You need a Cricut maker, a squeegee, and a heat press for this method. Heat transfer vinyl is a popular method for decorating shirts. Beginners and experts use it. HTV vinyl is a special vinyl with a decorative and adhesive side. The adhesive side sticks to the fabric when it is heated. With a cutting tool, you can cut out logos, graphics, and text from the vinyl.

Then, you heat seal them onto the fabric. Many artists use vinyl instead of ink to make raised and lasting designs on t-shirts. This is not really printing, but it looks good. Some professional businesses use big commercial cutting machines to make vinyl designs. But you can also make your vinyl cut-outs with a simple electronic cutting tool like a Cricut.

You can find different types of vinyl, such as glitter, velvet, and metallic vinyl. Heat transfer vinyl is good for small orders or home use. You only need a cutting machine and an iron to make t-shirts for your kid’s basketball team. You can start a small business with a Cricut and a heat press.

Pros

●Less time and effort

●Lower startup cost

●More durable than most printed designs

Cons

●Not effective for large orders

●Not suitable for heat-sensitive fabrics

Plastisol Printing

You need heat presses and transfer sheets for this method. Plastisol printing is a way of using screen printing skills and plastisol inks. Plastisol inks are the same as screen printing inks. The difference is that you do not print the ink directly on the fabric. You print the ink on a plastisol transfer sheet. Then you heat press the transfer sheet onto the t-shirt.

This makes a strong and lasting design on the shirt’s surface. Plastisol printing has the advantage of making high-quality designs. It is also less messy and faster than regular screen printing. You can also save money by outsourcing the printing of the Plastisol transfer sheet. You only need to make the digital design and have a heat press.

Pros

●Produces durable, high-quality designs

●Less mess and setup time

Cons

●Plastisol transfers might be difficult to apply

●Not effective for large orders

Conclusion

Shirt printing is a great way to show your style, grow your business, or earn some extra money. You can print shirts with different methods. Each one has its advantages and disadvantages. You can pick the best method based on your money, quality, and design requirements.

You can choose from heat press, DTG, screen, belt, dye sublimation, discharge, heat transfer vinyl, or plastisol printing. Whatever method you use, you can make incredible t-shirts that will wow your customers, friends, or yourself.

MGOO, a dedicated custom clothing provider, is here to support your clothing brand’s growth by offering all-inclusive services. If you plan to launch or expand a clothing line, MGOO can be your trusted partner. We simplify every step of the process, making it easy and secure.